The versatility of copper is astounding, the efficiency of the material makes it an attractive alternative for various applications. Over the years, copper has grown increasingly popular as its applications diversify. Various industries rely on this material for safe, reliable and efficient end-results.

The Plumbing Industry

Copper is one of the most durable piping materials available today, with a natural corrosion resistant characteristic. Copper can handle pressures of up to 1000 psi freezing and boiling temperatures without fail.

Because copper piping can last for decades and requires fewer replacements, repairs, and maintenance, it offers the best value.

Copper pipework systems are easy to install, a wide variety of jointing techniques exists, such as soldering, brazing, press, push-fit, compression and all are proven to be reliable and quick to install. Due to the efficiency and simplicity of copper, an increasing number of new constructions opt for copper piping!

Copper tubes and fittings have no rivals when it comes to proven performance!

Purchasing SABS approved copper tubing for water supply ensures that the dimensions of the pipes and fittings do not vary, this is often the case with other types of piping. This could create problems if the same system is not purchased from the supplier.

An Electrical favourite

Copper is the most conductive metal in the industry. This is due to the very high molecular structure and metallic band, electron concentration and mobility found in copper.

Electrical conductivity, which is the measure of how well a material transports an electric charge is an essential property in electrical wiring systems. Copper has the highest electrical conductivity rating of all non-precious metals.

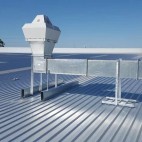

HVAC Systems

The Heating, Ventilation, Air Conditioning, and Refrigeration (HVAC(R) market is growing rapidly, the natural engineering properties of copper such as high conductivity, durability and workability have been an essential key player in the enhancement in design, increased product efficiency within the industry.

Bacteria, odours, mould and mildew and fouling can cause HVAC systems to function poorly, copper provides a solution to these common complications. It is a natural anti-fungal and anti-bacterial material, it can be looked at as an inexpensive anti-fungal and anti-mould agent that houses the capability to prevent fungal and mould growth.

Copper forms alloys more freely than most metals, with a wide range of alloying elements, such as zinc, tin, and nickel. These metals can be effectively added to increase strength and improve resistance to wear and corrosion when required.

Aquaculture

With aquaculture being one of the fastest growing sectors of the world food economy, copper alloys have become important netting materials for the industry. Various materials such as polyester, nylon, polyethylene, rubber etc. are some of the most common netting material in aquaculture fish enclosures, however, due to restricted material strength, additional nets often have to be installed. On the contrary, copper alloys carry strong structural properties that make it tough and resistant to predators.

Copper alloys exhibit low macro-organism attachment in seawater and freshwater which leads to cleaner mesh pens. This reduces the costs, fish stress and nuisance associated with conventional net changes. The resulting increased water exchange and dissolved oxygen improves fish health and welfare, leading to increased growth and development, lower mortality rates and improved feed conversion.

Copper qualities; strength and corrosion-resistance, make copper alloys a reliable material that is increasingly becoming the aquaculture netting material of choice worldwide.

Copper alloy mesh eliminates the need for routine net changing, lowering overall costs associated with maintenance and diver risk.

Expand your footprint, be part of a continental copper-consuming movement! For more information, visit the Copper Development Association Africa (CDAA)